ID-5001 LED Backlight Conversion

Version 3 with Linrose Super Brite White LED

Strips

Overview

The LED backlight conversion replaces the fluorescent lamp with LED strips of

equilavent brightness and greater reliability. The upgrade process

involves disabling the fluorescent circuit on the power supply board, removing

fluorescent lamp sockets, building the LED "board", and mounting a socket for a

2.1mm 12VDC power supply plug on the back of chassis.

The steps provide sufficient information for the experienced eletronics

hobbist.

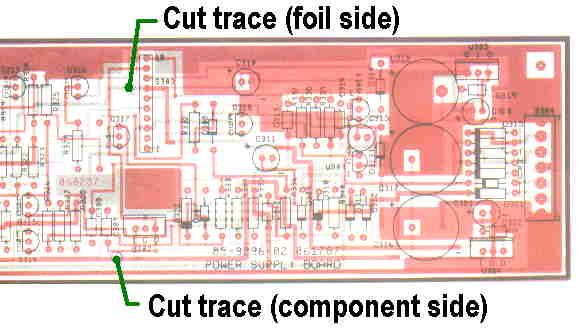

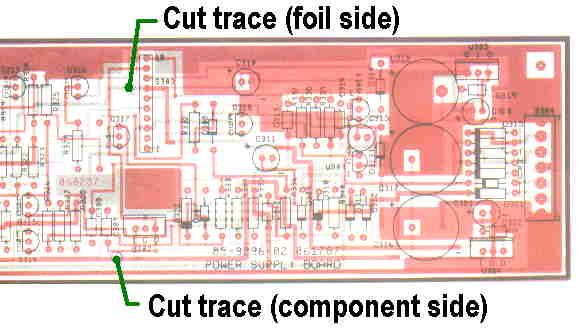

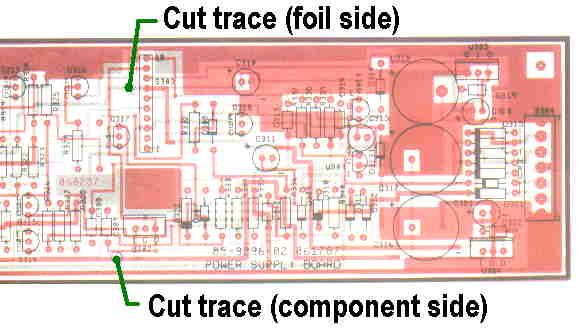

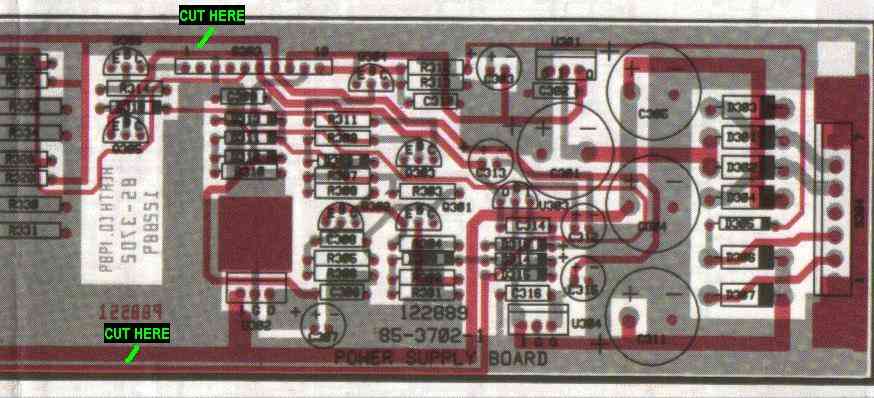

Figure 1. Power Supply Board Modifications

Original Power Supply Circuit

Board (1987)

Updated Power Supply Circuit Board (1989)

Parts

| Part number |

Description |

Quantity |

Unit Price* |

| B26LSM4-12V |

LED Flex Strip - 26 white surface mount LEDs |

2 |

$19.90 |

Other parts:

- 1" by 10" rigid plastic backer (approx. 0.05" thick)

- 12" of red 22 AWG wire, 12" of black 22 AWG wire

- Double-sided foam tape (alternately use hook-and-loop fastener -- e.g.,

Velcro).

- 12VDC 1A regulated power supply (e.g.,

Example)

- 5.5mm x 2.1mm DC Power Jack Socket Female Panel Mount Connector (e.g.,

Example)

* Prices may vary.

Assembly Instructions

Disassembly

- Disconnect ID-5001 from the wall power.

- Remove main cover and lamp cover.

- Remove the main circuit and power supply boards.

- Cut the two traces that supply power to

the fluorescent lamp (see Figure 3).

- Remove the lamp cover plate.

- Remove fluorescent lamp and lamp sockets.

- Reinstall the power supply and main circuit boards (see note for step 1

below).

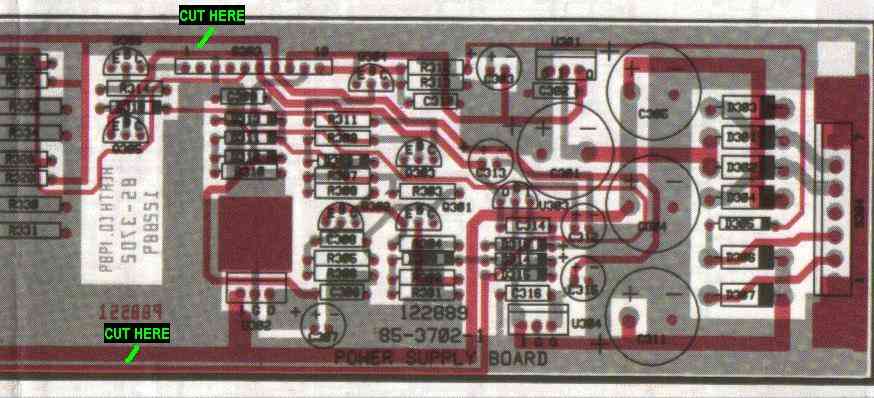

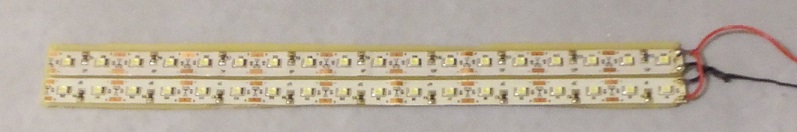

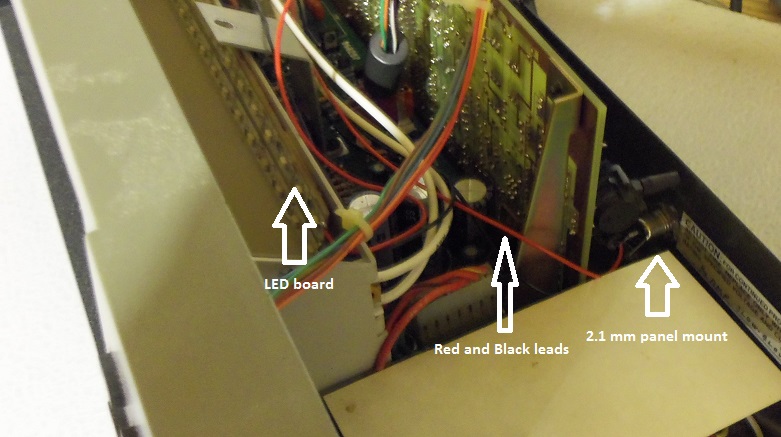

LED Board (refer to Figures 2 and 3)

- Mount the 2.1 mm Power Jack Socket Female Panel Mount Connector to the back of the chassis near where the AC power cord enters.

Note: it may be easier to mount the connector prior to reinstalling the

power supply and main circuit boards.

- Prepare 1" by 10" rigid plastic backer.

- Cut both LED strips to about 10" (cut strip only where indicated by the

markings on the strip itself).

- Remove LED strip backing to expose the adhesive. Affix to the

plastic backer.

- Prepare 10" red and black leads. Remove 1/4" insulation from each

end.

- Solder one end of the red 12" lead to the positive (+) solder point on

one end of the first LED strip.

- Solder one end of the black 12" lead to the negative (-) solder point on

one end of the first LED strip.

- Prepare 2" red and black leads. Remove 1/4" insulation from each

end.

- Solder one end of the 2" red lead to the positive (+) solder point on

one end of the second LED strip. Solder the other end of 2" red lead

to the same solder point in step 6.

- Solder one end of the 2" black lead to the negative (-) solder point on

one end of the second LED strip. Solder the other end of 2" black lead

to the same solder point in step 7.

- Apply 1" pieces of double-sided foam tape to both ends of the back the

plastic backer.

- Affix the plastic backer to the inside the light chamber in the previous

location of the fluorescent bulb. Route the red

and black leads through the gap between the sides of the light chamber to

the back of the chassis where the female 2.1 mm adpater is mounted and

solder the leads.

- Replace the light cover.

- Apply 12VDC to verify light operation.

- Replace chassis cover.

- Apply AC power.

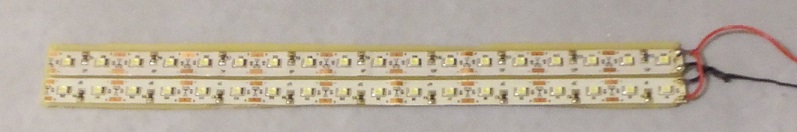

Figure 2. The LED board assembly

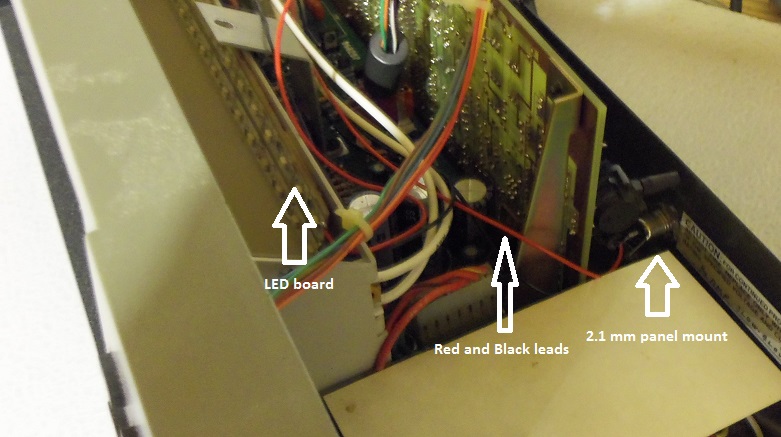

Figure 3. Final assembly

Disclaimers

Thunderhead

Technologies assumes no responsibly for the accuracy of the

ID-5001 LED Backlighting Conversion, availability of its

parts, its fitness for any purpose, or any damages - direct or

inconsequential - to persons or property.

The ID-5001 LED Backlighting Conversion is intended for

individuals experienced in electronics assembly. Consult a

qualified professional if you are unsure of your ability to

perform the required steps. Always follow safe practices while

working with electronics including wearing an anti-static wrist

strap to avoid damage to any electronic component.

Use of any vendors' parts does not constitute an endorsement of

that vendor.

Note: The LEDs will likely begin to very slowly dim after about 12 months.

Replace the LED strips to restore full brightness.

Last updated: November 4, 2016